|

|

03/20/2012 |

When I wrote about the Old Boston South Church one of the pictures I used was for some glorious interior molding. That molding was hand carved by highly skilled carvers and would have been very expensive. Carved moldings of various complexities were routinely used in the 19th century. Most lumber yards sold decorative molding, and doors like the one in the photograph would have been sold pre-made with the decorations already in place. Making the moldings was an industrial process far removed from the idyllic work of the country cabinetmaker working a treasured set of hollows and rounds. When I wrote about the Old Boston South Church one of the pictures I used was for some glorious interior molding. That molding was hand carved by highly skilled carvers and would have been very expensive. Carved moldings of various complexities were routinely used in the 19th century. Most lumber yards sold decorative molding, and doors like the one in the photograph would have been sold pre-made with the decorations already in place. Making the moldings was an industrial process far removed from the idyllic work of the country cabinetmaker working a treasured set of hollows and rounds.

While molding planes can be used for making straight moldings, mechanically cut moldings using rotary cutters dates from at least the 1850's (most probably earlier I need to research that). One advantage the rotary cutter has over a molding plane is that you can do curved moldings pretty easily. However neither a plane or a rotary shaper can produce a carved molding. To do that there are three methods that I can think of that were used to produce carved moldings in industrial quantities.

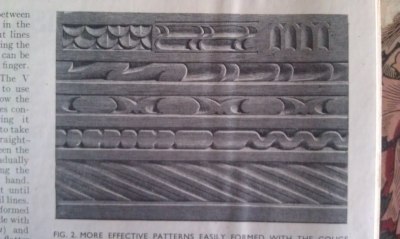

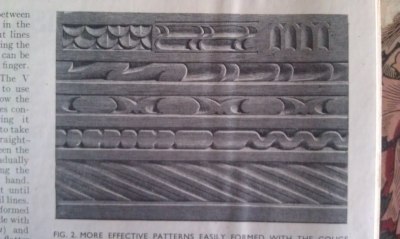

Hand carve them: This is the most obvious method and has been used for centuries. It's also the method most of us would use if we want to (and we should want to) incorporate carved moldings into a project. While the carvings in the Old South Church are very complex there is a fairly well documented series of simpler carved moldings, that were very popular, comparatively easy to do, and you could do them yourself if you wanted to. The book, Chris Pye's Woodcarving Course & Reference Manual has a whole chapter on simple moldings, This type of molding, also  seen at right in a photo from Charles Haywards' "Wood Carving for Beginners" were easily carved, with a very limited range of tools, in great quantities, by craftsman with minimal training. seen at right in a photo from Charles Haywards' "Wood Carving for Beginners" were easily carved, with a very limited range of tools, in great quantities, by craftsman with minimal training.

Mechanically tracing a pattern and carving with rotary burrs: I don't know when these machines were introduced but the last quarter of the 19th century is a good bet. These machines required a fair amount of tending and hand finishing, but it meant more complicated carvings could be mass produced. Here is a link to the carving machine section of the 1897 Chas. A. Strelinger & Company catalog.

Embossing the design: I have definitely seen the results but I cannot say anything about the details of the process where the carving is embossed on the wood with stamps. This works for fairly complicated designs, in low relief, with no crisp details. As early as the 1825 edition of Mechanics Magazine a Mr. John Straker details a process of embossing a design on wood, then either planing or filing off the high spots to level the wood again, and then soaking the wood to swell the wood and bring out the design. I am not sure if this method was ever adopted, or if stronger presses later in the century meant that you could just emboss in the background of whatever design you wanted and not worry about crushing and swelling.

In other news, just a reminder. On Friday, exactly 133 years after the original publication, our Work Magazine Reprint Project goes live with the first issue.

|

Join the conversation |

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

When I wrote about the

When I wrote about the  seen at right in a photo from Charles Haywards' "Wood Carving for Beginners" were easily carved, with a very limited range of tools, in great quantities, by craftsman with minimal training.

seen at right in a photo from Charles Haywards' "Wood Carving for Beginners" were easily carved, with a very limited range of tools, in great quantities, by craftsman with minimal training.